Hordhac ku saabsan kalsiyum

Calcite waa macdan kaarboonat kaalshiyam ah, oo inta badan ka kooban CaCO3. Guud ahaan waa mid hufan, midab la'aan ah ama caddaan ah, mararka qaarna isku dhafan. Halabuurka kiimikada aragtiyeed waa: Cao: 56.03%, CO2: 43.97%, kaas oo inta badan lagu beddelo isomorphism sida MgO, FeO iyo MnO. Adkaanshaha Mohs waa 3, cufnaanta waa 2.6-2.94, oo leh dhalaal galaas ah. Calcite ee Shiinaha waxaa inta badan lagu qaybiyaa Guangxi, Jiangxi iyo Hunan. Calcite Guangxi waxay caan ku tahay caddaankeeda sare iyo walxaha aan aashitada lahayn ee suuqa gudaha. Calcite waxaa sidoo kale laga heli karaa waqooyi-bari ee Waqooyiga Shiinaha, laakiin badanaa waxaa la socda dolomite. Cadaanta guud ahaan waxay ka hooseysaa 94, aashitada aan milmi karinna aad bay u sarreysaa.

Isticmaalka kalsiyum

1. Gudaha 200 oo mesh:

Waxaa loo isticmaali karaa waxyaabo lagu daro quudinta oo kala duwan oo leh kaalshiyam ka badan 55.6% oo aan lahayn walxo waxyeello leh.

2.250 shabaq ilaa 300 shabaq:

Waxaa loo isticmaalaa sidii walxo ceeriin ah iyo rinjiyeyn derbi gudaha iyo dibadda ah oo laga sameeyay warshad balaastig ah, warshad caag ah, warshad dahaadh ah iyo warshadda walxaha biyaha celiya. Cadaanku wuxuu ka sarreeyaa 85 digrii.

3.350 shabaq ilaa 400 shabaq:

Waxaa loo isticmaalaa soo saarista saxanka gusset, tuubooyinka hoos u dhaadhaca iyo warshadaha kiimikada. Cadaanku wuxuu ka sarreeyaa 93 digrii.

4.400 shabaq ilaa 600 shabaq:

Waxaa loo isticmaali karaa daawada cadayga, koolada iyo saabuunta. Cadaanku wuxuu ka sarreeyaa 94 digrii

5.800 mesh:

Waxaa loo isticmaalaa caag, balaastik, fiilooyin iyo PVC oo leh cadaan ka sarreeya 94 darajo.

6. Ka sarreeya 1250 mesh

Pvc, PE, Rinjiga, alaabada heerka dahaarka, rinjiyeynta warqadda, dahaarka dusha sare ee warqadda, caddaan ka sarreeya 95 digrii. Waxay leedahay daahirnimo sare, caddaan sare, aan sun ahayn, ur lahayn, saliid fiican, tayo hoose iyo adkaansho hoose.

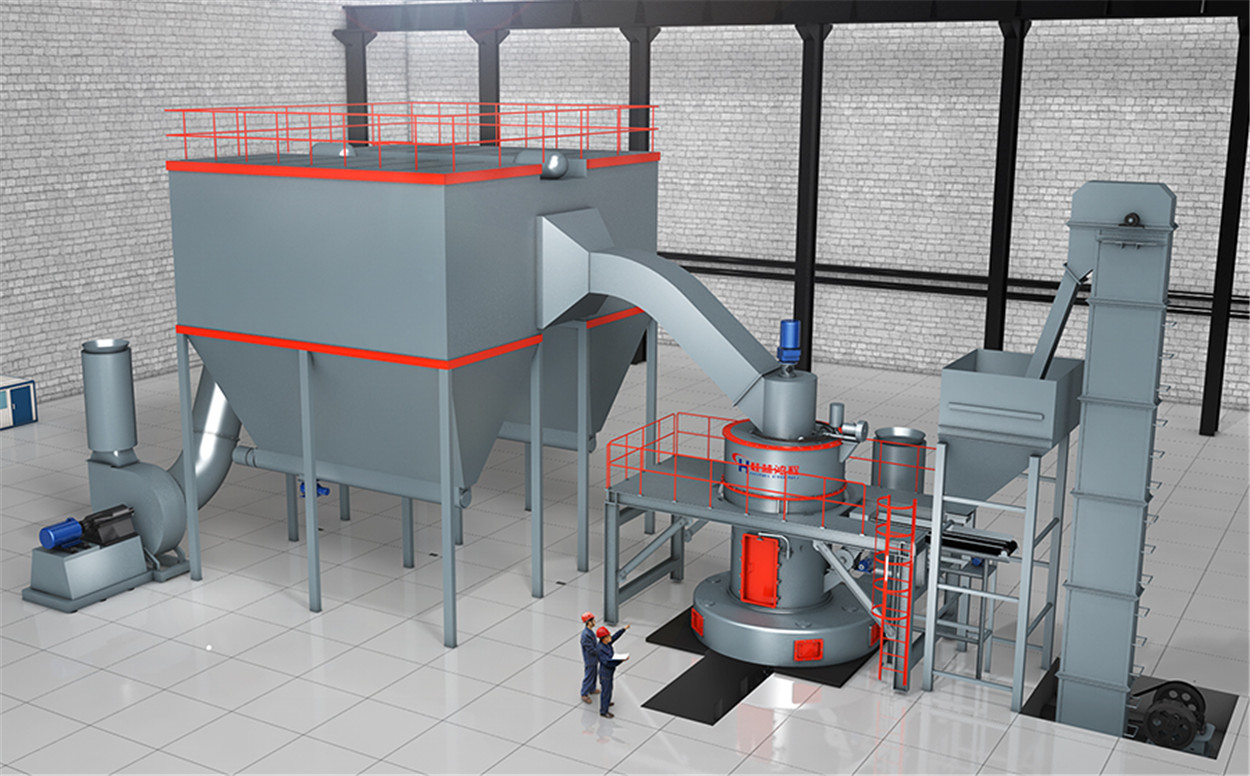

Habka Shiididda Calcite

Samaynta budada Calcite guud ahaan waxay u qaybsan tahay habaynta budada calcite fine (20 mesh - 400 mesh), habaynta qoto dheer ee budada calcite ultra-fine (400 mesh - 1250 mesh) iyo habaynta budada yar yar (1250 mesh - 3250 mesh)

Falanqaynta qaybaha ee walxaha ceeriin ee kalsiyumka

| CaO | MgO | Al2O3 | Fe2O3 | SiO2 | Tirada toogashada | Tusmada shaqada shiidida (kWh/t) |

| 53-55 | 0.30-0.36 | 0.16-0.21 | 0.06-0.07 | 0.36-0.44 | 42-43 | 9.24 (Mohs's: 2.9-3.0) |

Barnaamijka xulashada moodeelka mashiinka sameynta budada Calcite

| Qeexitaanka Badeecada (shash) | 80-400 | 600 | 800 | 1250-2500 |

| Nidaamka Xulashada Moodeelka | Taxanaha R Shiidida Taxanaha HC Shiidida Taxanaha HCQ Shiidida Taxanaha HLM Shiidida Toosan | Taxanaha R Shiidida Taxanaha HC Shiidida Taxanaha HCQ Shiidida Taxanaha HLM Shiidida Toosan Taxanaha HCH Shiidida Ultra-fine | Taxanaha HLM Vertical Mill HCH Mill + kala-sooc aad u fiican | Warshadda Toosan ee HLM (+kala-saare) Taxanaha HCH Warshadda Aad u fiican |

* Fiiro gaar ah: dooro mashiinka ugu weyn iyadoo loo eegayo shuruudaha wax soo saarka iyo tayada

Falanqaynta moodooyinka shiididda shiididda

1. Raymond Mill, warshadda shiidi karta ee taxanaha HC: kharashyo maalgashi oo hooseeya, awood sare, isticmaalka tamarta oo hooseeya, xasilloonida qalabka, buuq yar; waa qalabka ugu habboon ee lagu farsameeyo budada kalsiyum. Laakiin heerka baaxadda weyn ayaa si yar uga hooseeya marka loo eego warshadda shiidi karta ee toosan.

2. Mashiinka toosan ee HLM: qalab ballaaran, awood sare, si loo daboolo baahida wax soo saarka ee baaxadda weyn. Badeecadu waxay leedahay heer sare oo wareegsan, tayo wanaagsan, laakiin kharashka maalgashiga ayaa sarreeya.

3. Mashiinka shiididda ee HCH ee ultrafine: Mashiinka shiididda ee ultrafine waa qalab wax ku ool ah, keydin tamar, dhaqaale ahaan iyo wax ku ool ah oo loogu talagalay budada ultrafine in ka badan 600 oo meshes.

4. HLMX warshad toosan oo aad u fiican: gaar ahaan awoodda wax soo saarka ee baaxadda weyn budada ultrafine ee ka badan 600 oo meshes, ama macaamiil leh shuruudo sare oo ku saabsan qaabka walxaha budada ah, warshad toosan oo HLMX ultrafine ah ayaa ah doorashada ugu fiican.

Marxaladda I: Burburinta walxaha ceeriin ah

Maaddooyinka waaweyn ee kalsiyum-ka waxaa burburiya jajabiyaha si uu u noqdo mid jilicsan (15mm-50mm) oo geli kara warshadda shiididda.

Marxaladda II: shiidi

Alaabada yaryar ee calcite-ka ee la jajabiyey waxaa loo diraa meesha lagu kaydiyo iyadoo la adeegsanayo wiishka, ka dibna waxaa loo diraa qolka shiidi ee warshadda si siman oo tiro ahaan ah iyadoo la adeegsanayo quudiyaha si uu u shiido.

Marxaladda III: Kala-soocidda

Alaabada la shiiday waxaa lagu qiimeeyaa nidaamka kala-soocidda, budada aan u qalminna waxaa qiimeeya kala-soocidda waxaana lagu celiyaa mashiinka ugu weyn si loogu shiido.

Marxaladda V: Ururinta alaabta la dhammeeyay

Budada u hoggaansanta jilicsanaanta ayaa dhex marta dhuumaha gaaska waxayna gashaa ururinta boodhka si loo kala saaro loona ururiyo. Budada la ururiyey waxaa loo diraa qalabka wax lagu qaado iyadoo loo marayo dekedda laga soo saaro, ka dibna waxaa baakadeeya booyada budada ama qalabka baakadaha otomaatiga ah.

Nooca warshadda ee la dabaqi karo:

Taxanaha HC Taxanaha weyn ee shiididda pendulum (Waxaa loogu talagalay budada qallafsan ee ka hooseysa 600 mesh, iyadoo kharashka maalgashiga qalabka uu hooseeyo iyo isticmaalka tamarta oo hooseeya)

Mashiinka shiididda toosan ee HLMX Taxanaha superfine (Qalabka waaweyn iyo wax soo saarka sare waxay dabooli karaan wax soo saar ballaaran. Mashiinka shiididda toosan wuxuu leeyahay xasillooni sare. Qasaarooyinka: kharashka maalgashiga qalabka oo sarreeya.)

Mashiinka ultrafine-ka ee HCH (Soo saarista budada aadka u fiican waxay leedahay faa'iidooyinka isticmaalka tamarta oo hooseeya iyo kharashka maalgashiga qalabka oo hooseeya. Rajada suuqa ee warshadda ringroll-ka ee baaxadda weyn waa mid wanaagsan. Qasaarooyinka: wax soo saar hooseeya.)

Tusaalooyinka isticmaalka ee habka loo farsameeyo budada kalsiyum

wax ka-soo-saarka: calcite

Cufnaan: 325mesh D97

Awoodda: 8-10t/saacaddii

Qaabeynta qalabka: 1set HC1300

Soo saarista budada oo leh isla qeexitaan, wax soo saarka hc1300 wuxuu ku dhawaad 2 tan ka sarreeyaa kan mashiinka 5R ee dhaqameed, isticmaalka tamartana waa hooseeyaa. Nidaamka oo dhan si buuxda ayuu otomaatig u yahay. Shaqaaluhu waxay u baahan yihiin oo keliya inay ka shaqeeyaan qolka xakamaynta dhexe. Hawlgalku waa mid fudud oo badbaadiya kharashka shaqada. Haddii kharashka hawlgalku hooseeyo, alaabtu waxay noqon doontaa mid tartan badan. Intaa waxaa dheer, dhammaan naqshadeynta, hagitaanka rakibidda iyo fulinta mashruuca oo dhan waa bilaash, aad ayaan ugu qanacsannahay.

Waqtiga boostada: Oktoobar-22-2021